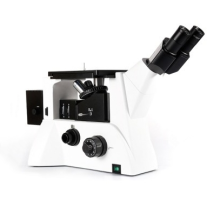

Trinocular Upright Metallurgical Microscope GL-CX40MW – Ideal for Metallographic Analysis and Industrial Inspection

GL-CX40MW Trinocular Upright Metallurgical Microscope – Advanced Metallographic Imaging Solution for Materials Analysis

The GL-CX40MW is a high-performance Trinocular Upright Metallurgical Microscope, specially designed for accurate and efficient metallographic structure analysis of metallic and alloy materials. Equipped with a precision infinity-corrected optical system, high eye-point wide field eyepieces, and professional metallurgical objectives, it ensures superior imaging for industrial inspection, materials science research, and teaching applications.

This computerized metallurgical microscope integrates a high-resolution Sony sensor digital camera and the FMIA2024 metallographic image analysis software, enabling real-time image capture, grain size measurement, spheroidization rate evaluation, phase percentage calculation, and automated metallurgical reporting.

Main features:

✅ Key Features:

- Infinity Plan Achromatic Objectives: Optimized for metallographic clarity and flat field imaging.

- Trinocular Head: Supports camera integration for digital imaging and live display.

- High-Resolution Sony Digital Camera: Delivers crisp, true-color images for documentation and analysis.

- Polarization Mode: Allows for polarized light observation of anisotropic microstructures and coatings.

- FMIA2024 Metallographic Analysis Software: Advanced grain size, pearlite rating, martensite structure, and graphite shape evaluation tools.

- Applications: Ideal for grain size analysis, heat treatment validation, phase differentiation, failure analysis, and academic training.

Included components:

- Microscope with reflective model mainframe

- Metallographic analysis software (English version)

- 12-megapixel camera device with USB 2.0 interface

- 0.5X adapter lens interface